NRCA has released The NRCA Roofing Manual: Steep-slope Roof Systems–2025. The new volume supersedes the previous edition published in 2021 and joins three other volumes in The NRCA Roofing Manual series. The complete current set includes:

- The NRCA Roofing Manual: Steep-slope Roof Systems–2025

- The NRCA Roofing Manual: Metal Panel and SPF Roof Systems–2024

- The NRCA Roofing Manual: Membrane Roof Systems–2023

- The NRCA Roofing Manual: Architectural Metal Flashing and Condensation and Air Leakage Control–2022

The steep-slope manual presents time-tested best practices and technical information concerning the design, materials and installation of steep-slope roof systems. It is intended for designers developing steep-slope roof system designs for specific projects. NRCA defines steep-slope roof systems as a category that generally includes water-shedding types of roof coverings installed on slopes exceeding 3:12.

How it is organized

The steep-slope manual addresses five roof covering types and includes an appendix. Asphalt shingle roof systems, clay and concrete tile roof systems, metal shingle roof systems, slate roof systems, and wood shake and shingle roof systems each have a dedicated section to serve as self-contained references for designers.

Each section is organized as follows:

- Chapter 1—Roof Assembly Configurations provides descriptions of roof assembly configurations based on best practices. The configurations reference detailed information in later chapters intended to help a designer select materials and practices suitable for a specific project.

- Chapters 2 through 5 address roof decks, underlayment, primary roof covering and roof accessories.

- Chapter 6 addresses roof system replacement and roof re-cover applications, except for clay and concrete tile, slate and wood shake and wood shingle roof systems.

- Chapter 7 contains construction drawings for common detail conditions that must be addressed in steep-slope roof system installations.

- An appendix about building code compliance based on the International Building Code,® 2024 Edition and International Residential Code,® 2024 Edition, rounds out each self-contained section.

A separate appendixes section contains information about topics not addressed in detail in the main body of the manual, including radiant barriers, synthetic roof covering products, designing steep-slope roof systems for wind resistance and Insurance Institute for Business & Home Safety FORTIFIED Roof™ program provisions for steep-slope roof assemblies.

The new manual introduces a long list of revisions. The deck and underlayment chapters include the greatest concentration of changes. Revisions related to updated code requirements for wind resistance are found throughout the manual, including appendixes. Also, new construction details were added to all roof covering-specific sections.

NRCA no longer recommends oriented strand board wood panels be used as substrates for steep-slope roof systems

Roof decks

With this update, NRCA no longer recommends oriented strand board wood panels be used as substrates for steep-slope roof systems because NRCA is concerned with OSB’s long-term performance. Experience has shown OSB is subject to dimensional changes, ridging and fastener backout resulting from changing moisture conditions roof deck substrates typically encounter.

When encountering existing OSB wood panel roof decks in roof replacement scenarios, NRCA suggests designers consider replacing OSB with new plywood panels or installing new plywood panels over existing OSB panels in good condition.

NRCA recommends plywood panels intended for use as roof sheathing in steep-slope roof assemblies meet or exceed the requirements set forth by U.S. Product Standards (PS) PS 1, “Construction and Industrial Plywood.”

NRCA also increased its minimum plywood roof sheathing thickness recommendation for asphalt shingle, metal shingle, and wood shake and shingle applications from nominal ½ of an inch to 5/8 of an inch nominal thickness for 16-inch rafter spacings and from 5/8 of an inch to 3/4 of an inch nominal thickness for 24-inch rafter spacings. These new recommendations are consistent with NRCA’s existing recommendations for clay and concrete tile and slate applications.

Chapter 6—Reroofing includes updated recommendations for the attachment of wood panel roof deck sheathing based on IRC 2024 provisions.

Nail-base insulation

Expanded and updated NRCA recommendations for nail-base insulation address problems commonly reported where nonvented or vented nail-base insulation is used in steep-slope roof assemblies.

When nail-base insulation is used, a base layer of polyisocyanurate board insulation should be installed first followed by nail-base insulation panels with all nail-base joints offset from the base layer joints and fastened to the structural deck.

Self-adhering flashing tape should be installed over all vented nail-base joints to seal all air gaps and confine the airflow to the ventilating space.

Designers using vented nail-base insulation in areas with a history of ice damming should upsize the ventilation space to prevent ice buildup at eaves.

NRCA cautions designers about using nail-base insulation products manufactured with fire-retardant-treated wood panels and does not recommend them as a fastening substrate for steep-slope roof systems.

Other deck types

The deck and reroofing chapters address structural composite decks and faced and sealed wood sheathing. Structural composite roof decks are marketed under the Loadmaster brand and engineered for specific applications and assembled in place from corrugated steel panels and fiberglass-reinforced gypsum panels and may include polyisocyanurate board insulation. When a steep-slope roof system is to be installed over a structural composite roof deck, NRCA recommends an appropriately designed nailable substrate of plywood panels, wood planks or wood boards, or spaced wood sheathing be installed over the structural composite roof deck to provide an adequate substrate for the steep-slope roof system.

Faced and sealed wood sheathing roof decks are marketed under the ZIP System® brand and are constructed of OSB panels with integral water-resistant facings and flashing tape applied over panel joints. NRCA recommends installing single-layer mechanically attached underlayment fastened in accordance with building code requirements over faced and sealed wood sheathing roof decks.

Other components

Chapter 3 has updated information about synthetic underlayment. IBC 2024 and IRC 2024 permit synthetic underlayment sheets that comply with ASTM D8257, “Standard Specification for Mechanically Attached Polymeric Roof Underlayment Used in Steep Slope Roofing,” to be used on asphalt shingle, clay and concrete tile, metal shingle and slate roof systems. NRCA recommends designers select materials complying with ASTM D8257 and specify the minimum water vapor transmission rating when specifying synthetic underlayment.

Chapter 3 also addresses taped deck underlayment applications. In these applications, self-adhering flashing tape is applied over all joints in the roof sheathing and a single layer of underlayment is then fastened. A taped deck application is intended to prevent water entry through roof sheathing joints and is one of the prescriptive options IBC 2024 and IRC 2024 provide for steep-slope roof system underlayment in high-wind regions. Chapter 3 also adds an illustration of double-layer underlayment attachment in high-wind regions, which is another prescriptive code option for asphalt shingle and clay and concrete tile roof systems in high-wind regions.

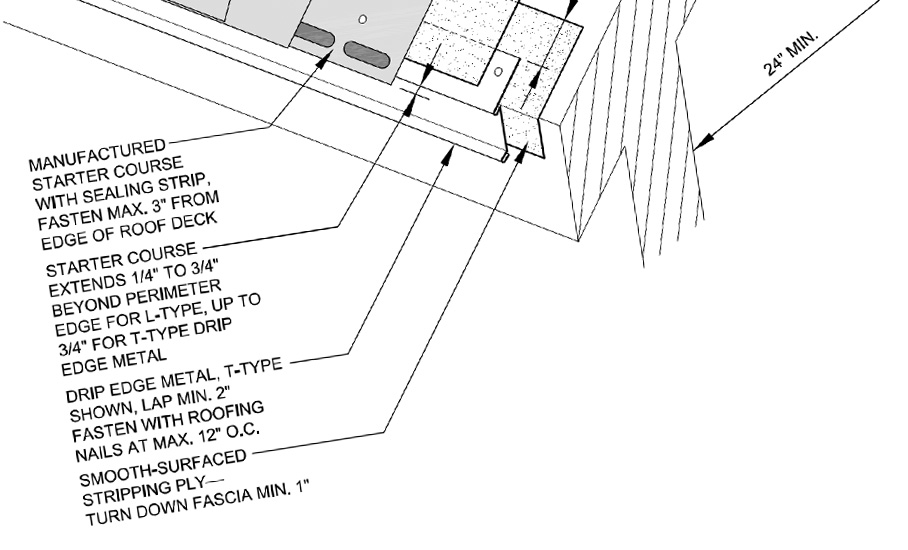

NRCA has revised its best-practice recommendation for detailing eaves with water and ice-dam protection underlayment. First, a self-adhering polymer-modified bitumen sheet stripping ply is applied directly to the deck at the eave edge and turned-down fascia. Drip-edge metal is fastened over the stripping ply and then a full sheet of water and ice-dam protection underlayment is applied.

With this update, NRCA recommends the use of drip-edge metal at all eaves and exposed rakes for clay and concrete tile, slate, and wood shake and shingle roof systems.

Wind resistance

The manual references IBC 2024 and IRC 2024 wind resistance provisions and includes updated wind design maps based on ASCE 7-22, “Minimum Design Loads and Associated Criteria for Buildings and Other Structures.”

An expanded and updated Appendix 3—Wind Uplift for Steep-slope Roof Systems explains in considerable detail the methods ASCE 7-22 specifies for determining design wind loads for steep-slope roof systems. The appendix also discusses selecting an appropriate wind-resistant roof system as well as the responsibilities assigned to designers by building code for properly determining and clearly identifying wind design data.

Appendix 4—FORTIFIED Roof™ Requirements is new for 2025. It is a guide to the FORITFIED Roof portion of IBHS’s FORTIFIED Home™ standard for resilient home construction. The appendix includes 20 construction drawings. FORTIFIED Roof specifies steep-slope roof assembly construction enhancements for new and retrofit applications intended to increase roof assembly resistance to damage from natural hazards such as hurricane-strength winds and hail. The taped deck underlayment application provisions in current I-Codes originated with the FORTIFIED Home program.

Construction details

All primary details for the treatment of eaves with water and ice-dam protection underlayment have been revised to include a self-adhering stripping ply applied directly to the deck and turned-down fascia a minimum of 1 inch. The same revision has been applied to the corresponding eave with gutter details.

There are new details for hot exhaust vents and rooftop equipment curbs in each roof covering-specific section.

Revised clay and concrete tile, metal shingle and slate roof system steep- to low-slope transition details include a two-piece sheet-metal flashing.

How to get it

You can purchase electronic or hard copy versions of the new manual at shop.nrca.net. NRCA members can download the manual as well as NRCA Construction Details: CAD Files—2025, which includes the updated NRCA steep-slope roof system construction details, free of charge at shop.nrca.net.

Maciek Rupar

Director of technical services

NRCA

-1.jpg)