The NRCA Waterproofing Manual provides a number of options for membrane types used in waterproofing applications. Most waterproofing membranes cannot be exposed to ultraviolet (UV) light; however, fluid-applied elastomeric waterproofing membranes are well-suited for continual UV exposure.

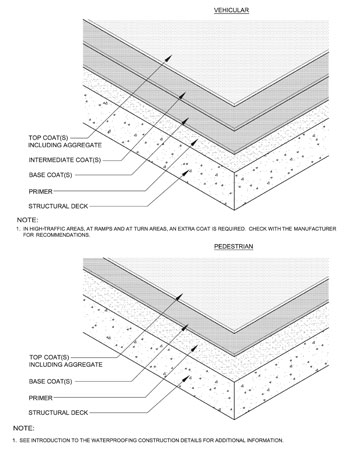

Detail WP-39, "Traffic-bearing waterproofing membrane," provides information for the two common installation categories of fluid-applied elastomeric membranes: vehicular and pedestrian. These types of waterproofing systems commonly are used for exposed concrete structures, such as parking garages and balconies.

NRCA coat provides additional toughness and durability; and a top coat provides color options and UV resistance for a waterproofing system. Base, intermediate and top coats typically are one- or two-part self-leveling products.

Detail 39 from The NRCA Waterproofing Manual

For most applications, a primer is needed to improve adhesion of a base coat to a substrate. To increase the slip resistances of traffic-bearing fluid-applied elastomeric coatings, a fine aggregate (such as sand, crushed walnut shells or metal oxide) can be broadcast and back-rolled into the top coat. Fluid-applied elastomeric coatings should not be installed over spalled or contaminated concrete surfaces.

Fluid-applied elastomeric waterproofing membranes also can be used for covered (non-UV-exposed) waterproofing systems. They are appropriate for use beneath slabs below grade where an appropriate substrate is in place; as positive (exterior) side waterproofing for walls below grade; and as waterproofing membranes for planters, fountains, pools, ponds, lagoons and reservoirs with concrete, masonry or wood substrates. Elastomeric pedestrian coatings should not be used in split-slab or slab-on-grade constructions because of the possibility of moisture entrapment.

James R. Kirby, AIA, is an NRCA senior director of technical services.