Environmental Product Declarations are an increasingly important tool in the construction industry, particularly for roofing contractors. As sustainability and environmental responsibility gain traction, EPDs provide a standardized way to communicate the environmental impact of roofing products.

It’s important to understand what EPDs are, why they matter, how they are being integrated into projects and what you can do to prepare for their use. Those who take proactive steps to understand and implement EPDs will be well-positioned to meet the demands of a more sustainable future.

What are EPDs?

EPDs are Type III environmental labels as defined by ISO 14025, “Environmental labels and declarations—Type III environmental declarations—Principles and procedures.” They provide a comprehensive summary of products’ environmental impacts based on a life-cycle assessment.

Two standards detail the requirements for conducting a life-cycle assessment: ISO 14040, “Environmental Management-Life Cycle Assessment-Principles and Framework,” and ISO 14044, “Environmental Management-Life Cycle Assessment–Requirements and Guidelines.”

A life-cycle assessment determines the potential environmental impacts of a product from raw material extraction (cradle) through manufacturing, use and disposal (grave). EPDs are peer-reviewed and provide transparent, comparable data for the environmental performance of products. All EPDs are developed according to a product category rule.

Product category rules

Product category rules provide a standardized framework for conducting life-cycle assessments and creating EPDs for specific product categories. In the U.S., EPDs for building products are based on the core product category rule ISO 21930, “Sustainability in buildings and civil engineering works—Core rules for environmental product declarations of construction products and services.”

Product category rules ensure EPDs for similar products are consistent and comparable, which is essential for making informed decisions about materials’ environmental impacts. The key elements of a product category rule include requirements related to scope, product category definition, declared or functional unit, system boundary, data collection and calculation methodologies, environmental impact categories, and verification and validity. There are subcategory product category rules for roof coatings, asphalt roofing and single-ply roof membranes.

Those who take proactive steps to implement EPDs will be well-positioned to meet the demands of a sustainable future.

Scope and definition

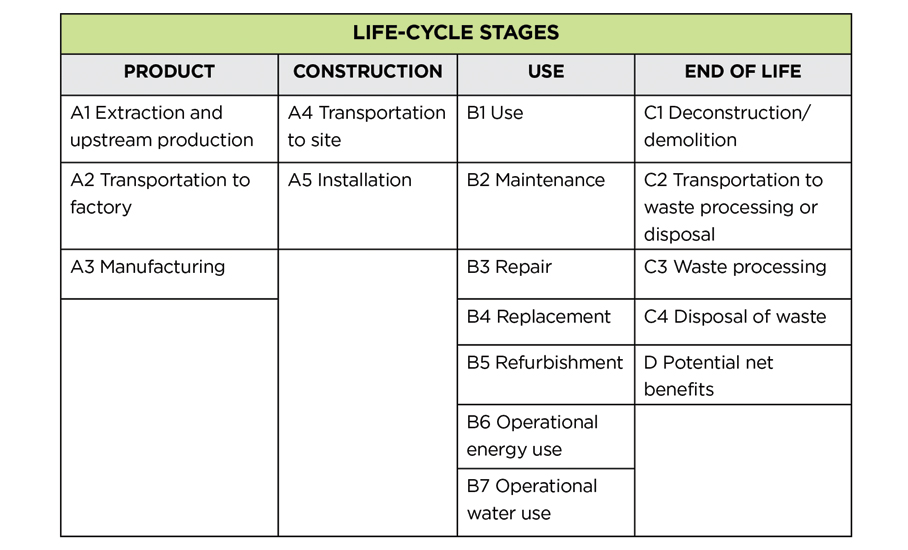

Product category rules define the product category and scope of the life-cycle assessment, including the life-cycle stages to be assessed. The scope determines which stages of a product’s life cycle are included in an EPD, such as raw material extraction, manufacturing, transportation, use and end-of-life disposal. Life-cycle stages and modules are defined in ISO 21930 and shown in the figure on page 40.

The minimum life cycle for which an EPD can be created is the production stage (A1-A3). This represents the life-cycle stages over which manufacturers have the greatest control. When all life-cycle stages are included in the analysis (A1-A5, B1-B7 and C1-C4), it is said to have a cradle-to-grave scope.

Declared or functional unit

The functional unit is the reference unit for environmental data such as per square meter or per ton of roofing material. The functional unit ensures environmental impacts are reported consistently, allowing for fair comparisons between products. Declared units are possible when an EPD is created for a full, cradle-to-grave life cycle, which incorporates the function of the product and any performance requirements.

System boundaries

System boundaries define what is included and excluded in the life-cycle assessment, such as specific processes, mate-rials or energy sources. These boundaries ensure a life-cycle assessment is comprehensive and all relevant environmental impacts have been considered.

Data and calculation

Product category rules specify the methods for collecting data and calculating environmental impacts. Standardized methods ensure life-cycle assessment results are accurate and comparable across different products and manufacturers.

Environmental impact

Product category rules define the environmental impact categories that must be reported in an EPD, such as global warming potential (also known as embodied carbon), ozone depletion potential and eutrophication potential (the potential to cause excess algae or plant growth in water). Consistent reporting of impact categories allows for meaningful comparisons between products and helps manufacturers identify areas for improvement.

Verification and validity

Product category rules outline the requirements for third-party verification of EPDs and EPDs’ validity periods (typically five years). Verification ensures the information reported in the EPD is accurate and complies with ISO standards without revealing any proprietary information a manufacturer may have disclosed as part of the background life-cycle assessment report.

U.S. requirements

Federal agencies, such as the General Services Administration and Federal Highway Administration, have been increasingly requiring EPDs for materials used in federal construction projects. This is part of a broader push toward sustainable building practices and reducing the carbon footprint of federal buildings.

California has been a leader in environmental regulations, and EPDs are no exception. The state’s Buy Clean California Act requires all steel, glass and mineral wool insulation used in state-funded projects have EPDs. Although roofing materials are not explicitly mentioned, the trend suggests they may soon be included.

Similarly, Washington state’s Clean Buildings Standard includes requirements for EPDs on certain building materials. The state also is exploring the inclusion of roofing materials in future updates to the standard.

Massachusetts has implemented the Massachusetts LEED Plus program, which requires EPDs for certain materials used in state-funded projects. Roofing materials increasingly are being included in these requirements.

New York City’s Local Law 97 aims to reduce greenhouse gas emissions from large buildings. Although the law focuses on operational emissions, it also encourages the use of low-carbon materials, which can be verified through EPDs.

In addition to federal, state and city agencies, there are several other entities that may require roofing contractors to provide EPDs for projects. These include:

- Educational institutions. Universities and colleges often are at the forefront of sustainability initiatives. Many educational institutions require EPDs for materials used in new construction or renovation projects as part of their commitments to reducing their environmental impact. Universities such as Harvard and Stanford have sustainability programs that include requirements for EPDs for building materials, including roofing products.

- Corporations. Large corporations, particularly those with strong sustainability commitments, may require EPDs for materials used in their office buildings, warehouses, data centers and other facilities. Companies such as Google, Amazon and Walmart have sustainability goals that include the use of low-carbon building materials. As an example, Google’s sustainability initiatives include requirements for EPDs for materials used in their data centers and office buildings.

- Building codes and certification programs. The International Green Construction Code® and certification programs such as LEED, Green Globes and the Living Building Challenge often require EPDs for materials used in certified projects. Although the IgCC requires EPDs on a certain number of products, certification programs provide points or credits for using materials with EPDs, which can help projects achieve higher levels of certification. For example, LEED v4.1 includes credits for using materials with EPDs, particularly those that are product-specific rather than those that meet the industry average.

- Architectural firms. Architectural firms focused on sustainable design may require EPDs for materials used in their projects regardless of whether doing so is a specific client priority. Several larger firms prioritize sustainability, meaning they require EPDs for all major building materials, including roofing products, to ensure their projects are transparent and meet sustainability goals as well as comply with regulatory requirements.

- Real estate developers. Real estate developers, particularly those focused on sustainable or green building projects, may require EPDs for materials used in their developments. This is especially true for high-profile projects that aim to achieve green building certifications or meet sustainability goals. Developers often require EPDs for materials used in their sustainable building projects.

Where to find EPDs

Finding EPDs for roofing materials is a critical step for contractors who need to comply with regulations or meet client requirements. There are several ways you can find EPDs.

Direct requests

Many roofing material manufacturers provide EPDs on their websites; look for a dedicated section on sustainability, documentation, en-vironmental performance or product transparency. If an EPD is not readily available online, most manufacturers are willing to provide EPDs upon request, especially for contractors working on large or high-profile projects. Smaller or specialty manufacturers may not publish EPDs online but can provide them via email or through their sales representatives.

EPD databases

Several online databases aggregate EPDs from multiple manufacturers and allow contractors to search for EPDs by product type, manufacturer or certification. Examples include buildingtransparency.org/tools/ec3 or mindfulmaterials.com/connected-data.

Suppliers

Roofing material distributors and suppliers also may have access to EPDs for the products they sell. You can request EPDs from your supplier, especially if you are working with specific brands or product lines. Large distributors may provide EPDs upon request or have them available on their websites.

Government websites

Some states or municipalities that require EPDs for public projects may provide links to approved EPDs or databases. These resources can be particularly useful when working on government-funded projects. For example, California provides information about EPD requirements and links to resources for finding compliant materials.

Be educated

As governments and municipalities push for greener building practices, EPDs are becoming a requirement in many jurisdictions. Roofing contractors must be aware of these requirements to ensure compliance, avoid potential penalties and meet client expectations.

To be on the forefront of this movement, keep abreast of local, state and federal regulations related to EPDs; consider attending workshops or webinars about the topic; and ensure your team is well-informed. In addition, work closely with roofing material manufacturers that provide EPDs. This will ensure compliance and give you a competitive edge in the market.

What you need to know

When collecting EPDs for roofing projects, you need to understand the key components of these documents to ensure they meet regulatory and client requirements. Here are the critical parts of an EPD and what to look for:

- Product category rules: Ensure an EPD is based on a recognized product category rule for the specific roofing product being used and ISO 21930. A product category rule should be clearly stated in the EPD. Most project requirements mandate the use of EPDs based on recognized product category rules.

- Life-cycle stages: Verify which life-cycle stages are covered. For roofing materials, a cradle-to-gate EPD (covering raw material extraction, manufacturing and transportation) is common, but some EPDs may report or projects may require a cradle-to-grave EPD (which also includes use and end-of-life stages).

- Declared or functional unit: Ensure the declared unit is appropriate for your project. If you are comparing different roofing materials, make sure the declared units are consistent (for example, both EPDs should report impacts per square meter).

- Environmental impacts: Focus on the metrics most relevant to your project or regulatory requirements. For instance, if your project aims to reduce carbon emissions, pay close attention to the global warming potential (measured in kg CO₂e).

- Verification and validity: Check the EPD has been verified and still is valid. The verification statement should be included on the document’s front page.

- Manufacturer information: Ensure manufacturer information listed on the EPD is for the product you are purchasing and the information is current.

Stay ahead of the curve

EPDs are becoming an essential part of the roofing industry. As regulatory requirements and client demands for sustainable building practices increase, roofing contractors must adapt to stay competitive. By understanding EPDs, staying informed about regulatory changes and partnering with manufacturers that provide EPDs, you can position yourself as a leader in the green building movement.

The integration of EPDs into state and city codes, as well as the requirements set by leading architectural firms, underscores the importance of these documents. Roofing contractors who embrace this trend not only will ensure compliance but also gain a significant advantage in the marketplace.

EMILY LORENZ, PE, F-ACI

Independent consultantin the areas of life-cycle assessments, environmental product declarations, product category rules, green building and sustainability.