Polyisocyanurate insulation manufacturers' faced, high-density polyisocyanurate insulation cover board products have gained popularity and acceptance in the U.S. roofing industry. Differences among some high-density products mean some products are not necessarily interchangeable or, using common specification language, they are not "or equal."

Product standard

The U.S. product standard for faced rigid cellular polyisocyanurate is ASTM C1289, "Standard Specification for Faced Rigid Cellular Polyisocyanurate Thermal Insulation Board." ASTM C1289 describes 18 types of polyisocyanurate products, including polyisocyanurate insulation wall sheathing, roof insulation and composite boards. The products are differentiated with ASTM C1289 by type and, in some cases, also class and grade. For example, the proper ASTM International designation for fiberglass-reinforced, cellulose-faced polyisocyanurate thermal insulation with a minimum 20 pounds per square inch (psi) compressive strength is ASTM C1289, Type II, Class 1, Grade 2. In this designation, Class 1 specifically designates the facer sheets and Grade 2 designates the board has a minimum 20-psi compressive strength.

Faced, high-density polyisocyanurate insulation cover board is designated as ASTM C1289, Type II, Class 4 followed by Grade 1, 2 or 3. Grade 1 designates a minimum 80-psi compressive strength; Grade 2 a minimum 110-psi compressive strength; and Grade 3 a minimum 140-psi compressive strength.

Faced, high-density polyisocyanurate insulation cover board

Faced, high-density polyisocyanurate insulation cover boards use coated polymer-bonded fiberglass facers similar to those used on ASTM C1289, Type II, Class 2 conventional polyisocyanurate insulation products.

Comparing faced, high-density polyisocyanurate insulation cover board to conventional polyisocyanurate insulation using ASTM C1289's physical requirements reveals high-density products have significantly higher compressive and flexural strengths and an allowable water absorption value two times or more than conventional polyisocyanurate insulation. Allowable dimensional stability values for faced, high-density polyisocyanurate insulation cover board are about half the values for conventional polyisocyanurate insulation used in roof systems in the length and width dimensions.

Comparing products

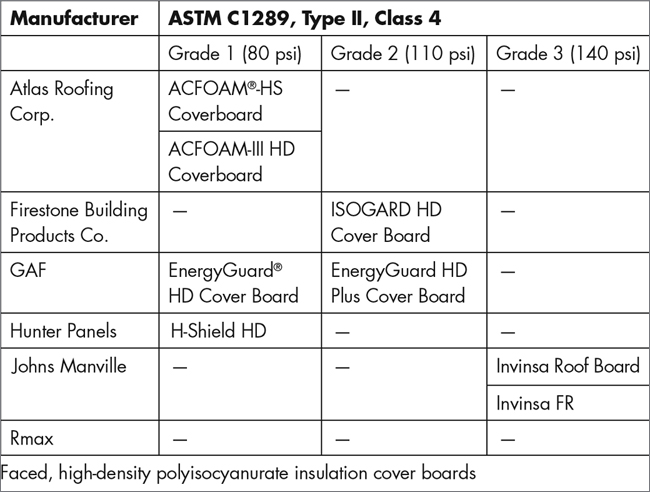

Review of polyisocyanurate insulation manufacturers' product literature reveals five of the six U.S. manufacturers of polyisocyanurate insulation produce one or more faced, high-density polyisocyanurate insulation cover board products; Rmax, Dallas, does not manufacture a high-density product.

Comparing the manufacturers' products reveals differences primarily based on products' minimum compressive strengths. The figure shows a categorization of manufacturers' faced, high-density polyisocyanurate insulation cover boards based on ASTM C1289, Type II, Class 4. Grade 2 products also comply with ASTM C1289, Type II, Class 4, Grade 1, and Grade 3 products also comply with ASTM C1289, Type II, Class 4, Grades 1 and 2.

NRCA's recommendations

For membrane roof systems, NRCA recommends designers specify a suitable cover board over polyisocyanurate and polystyrene thermal insulation. NRCA considers faced, high-density polyisocyanurate cover board to be a suitable cover board option for mechanically attached and adhered single-ply membrane roof systems. It also may be suitable in cold-applied and built-up membrane roof systems and cold-applied self-adhering polymer-modified bitumen roof systems.

Designers should specify faced, high-density polyisocyanurate cover board to be compatible with the membrane system and specific project requirements. NRCA recommends designers use the complete ASTM C1289 designation (including type, class and grade) to clearly delineate the specific product intended.

Mark S. Graham is NRCA's vice president of technical services.